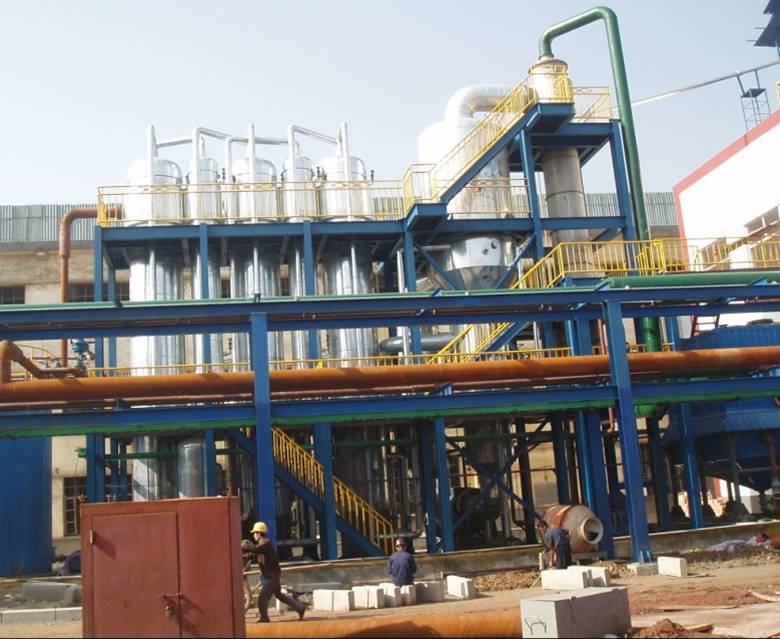

Crystallizers

RDG crystallizer systems are utilized for zero liquid discharge applications to convert diluted or concentrated salt solutions into solid salt crystals and clean water.

Crystallization is a solid-liquid separation technique in which solid crystals are formed from a liquid solution. Crystallizers can eliminate liquid wastes to create zero liquid discharge (ZLD). Crystallization is divided into two stages: primary nucleation and secondary nucleation. Primary nucleation involves the growth of new crystals. Secondary nucleation perpetuates growth and is the main stage that causes the mass production of crystals.

Our expertise includes the following crystallization process types:

- by concentration

- by cooling (under vacuum or with a heat exchanger)

- by reaction or equilibrium displacement

We possess the know-how and expertise for all of the following types of crystallization equipment with total or partial classification, involving the recirculation of the magma, with or without settling zones.

- Forced Circulation Crystallizer

- Oslo Type Crystallizer (classified-suspension crystallizer)

- DTB Crystallizer (draft – tube – baffle crystallizer)

- Induced Circulation Crystallizer

- Cooling Crystallizers

- Evaporative Crystallizers

- Freeze Crystallizers

- Melt Crystallizers

- Vacuum Crystallizers

Our staff engineers are able to design complete systems for custom applications, optimizing process efficiency and final discharge quality.